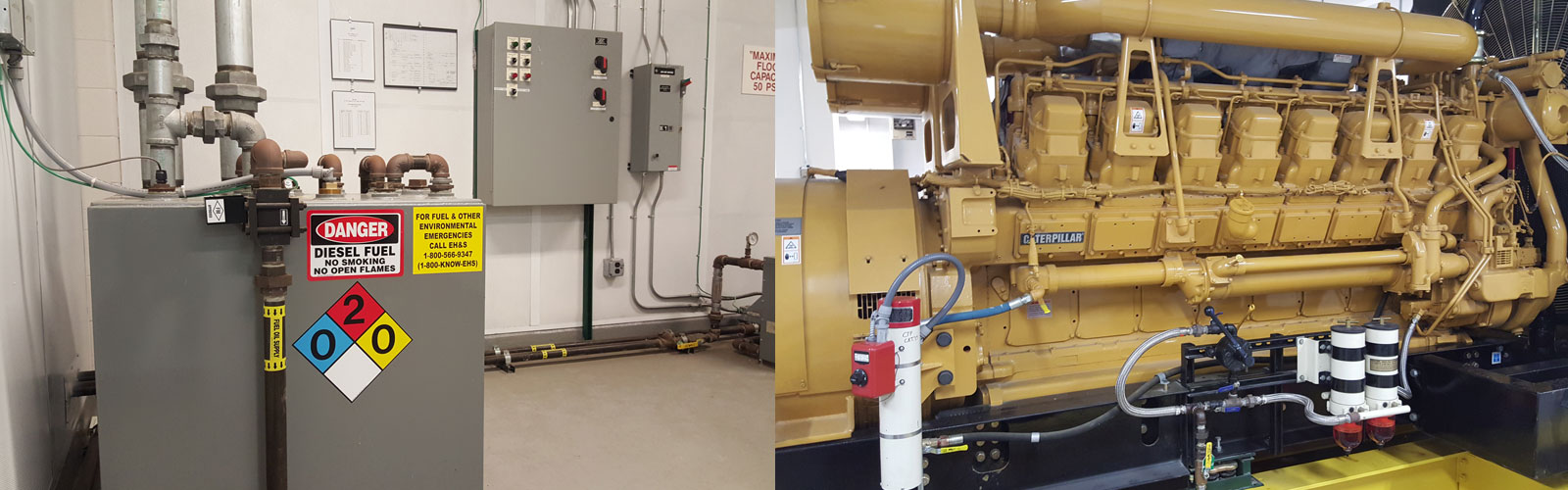

To obtain the maximum life from fuel system components, routine and proper maintenance is critical. Matzak Inc. is a leading Fuel System Maintenance Contractor.

The automatic tank gauge (ATG) will provide more accurate fuel and water level readings when the floats and probe shaft are cleaned periodically. Overfill prevention valves (commonly referred to as drop tubes or flapper valves) benefit greatly by removing and testing annually to prevent corrosion from seizing the valve in the fill riser. Dispenser filters should be monitored closely and changed according to amount of fuel dispensed, condition of the fuel, and desired GPM output. Any electrical junction boxes underneath grade manholes should be accessed yearly and anti-seize thread sealant applied to prevent corrosion from seizing the cover.

Fuel system components will benefit greatly and reward the owner/operator with an extended life when a simple, smart maintenance plan has been implemented. Maintenance plans can often be performed simultaneously during compliance driven inspections so as to diminish costs and repeat trips by the service contractor.

Deteriorating and failing fuel system components will leave you exposed to possible petroleum releases into the environment and compliance violations with state or federal regulatory agencies. Increase the life of the components by implementing a maintenance plan. To request a professional opinion on your existing fuel system, and to propose a sound maintenance plan, please Contact Us.