Most underground storage tanks, if installed properly, will last beyond the typical 30 year manufacturer warranty. Since the underground storage tank (UST) is buried, it is protected from ultraviolet rays, inclement weather, ground freeze/thaw cycle, vehicle traffic, snow plows, and road salt. However, components that mount to the UST which are at grade level will experience a shortened life span due to exposure to all of these conditions.

It is critical to keep the UST components working correctly and upgraded when needed. In the Midwest, spill containers can break down and fail after 5 to 7 years. If not removed periodically, overfill prevention valves will seize into fill risers, and grade access manholes will sooner or later become fatigued and not provide proper H-20 load ratings over the tank components.

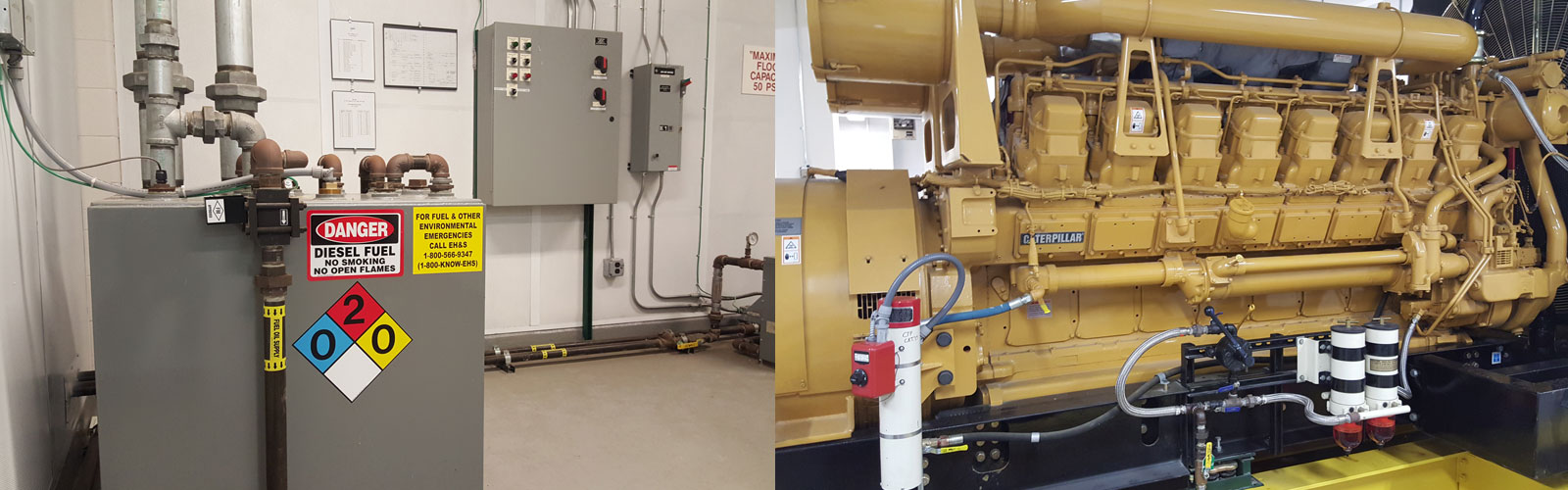

Aboveground storage tanks (AST) and associated components will experience similar failures to the UST components. Weather and ultraviolet rays will cause coating failure on the AST and piping. Corrosion will damage components disabling overfill alarms, anti-siphon valves, emergency vents, and dispensers. Damaged or nonworking components will leave the system nonoperational and its owner/operator exposed to potential compliance violations.

The tank component’s life is directly related to the installation practices of the installer. Make sure the install contractor has current certifications and follows all industry standards and manufacturer’s installation guidelines.

See our certifications and licenses on our Skilled Technicians page.

See some of our projects on our Projects page.

Deteriorating and failing fuel system components will leave you exposed to possible petroleum releases into the environment and compliance violations with state or federal regulatory agencies. To request a professional opinion on your existing fuel system, and to propose a good sound compliant component replacement, please Contact Us.