Petroleum Storage Tank & Fuel System FAQ: Regulations, Installation, Maintenance

What is an UST?

An UST, or Underground Storage Tank, are primarily used to store petroleum or diesel fuel products underground. USTs are found at service stations, connected to boilers/steam generators, or connected to emergency generators for businesses needing backup power. Underground Storage Tanks must be installed and inspected by certified contractors who strictly adhere to industry standards and manufacturer guidelines to prevent environmental contamination. Learn more about UST installation and maintenance.

What is an AST?

An AST, or Aboveground Storage Tank, is a large container, typically made of metal, that stores liquids or gases above the ground. These tanks are used for a variety of reasons, including fuel storage. Aboveground Storage Tanks must be installed and inspected by certified contractors who strictly adhere to industry standards and manufacturer guidelines to prevent environmental contamination. Learn more about AST installation and maintenance.

What is UDC?

UDC, or Under Dispenser Containment, is often referred to as a sump, as it is a collection point for gasoline leaks or drips. View a UDC replacement project.

How can my business extend the life of our fueling systems?

Preventative maintenance is highly recommended to extend the life of the fueling system, as well as maintain compliance requirements. Learn more about fuel system testing.

How can my business safely replace my underground (UST) petroleum tank storage?

Full system replacements can be accomplished safely and successfully by reviewing throughput, site plan footprint, system desires, budget, and compliant required features. Learn more about UST replacement.

How can my business safely replace our aboveground (AST) petroleum tank storage?

Full system replacements can be accomplished safely and successfully by reviewing throughput, site plan footprint, system desires, budget, and compliant required features. Learn more about AST replacement.

What are the implications of our fleet fueling system deteriorating?

Deteriorating and failing fuel system components will leave you exposed to possible petroleum releases into the environment and compliance violations with state or federal regulatory agencies. Learn more about fuel system repair and replacement.

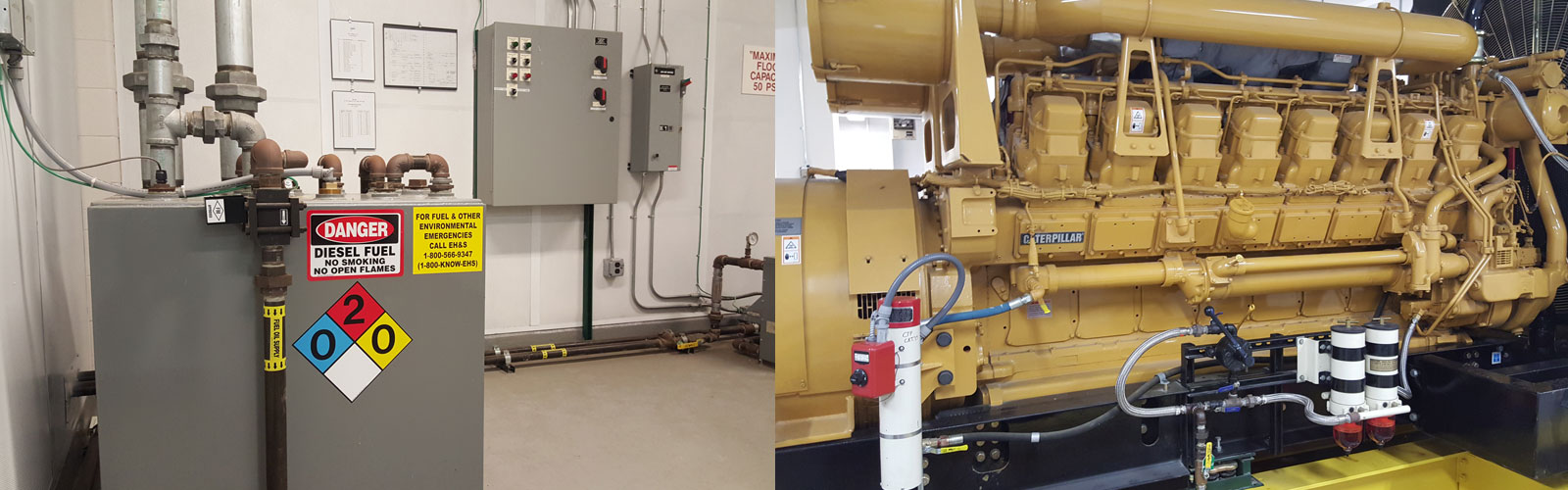

What is the best solution for my company’s fuel tank systems for emergency and backup power generators?

For enhanced reliability and maintainability, consider a custom-designed day tank system. This allows for remote mounting of pumps and controls, simplifying access for servicing and enabling the addition of critical components like pressure gauges and bypass valves. Learn more about day tanks and pump controls.

How does my business minimize environmental liability and financial risks from onsite fuel systems?

Regular inspections and maintenance are vital to avoid soil and groundwater contamination. In the event of a fuel leak, prompt action is necessary. The complexity and expense of petroleum spill cleanup depend on factors like groundwater and soil conditions. Retain an experienced environmental professional for guidance on remediation options and regulatory reporting. Learn more about fuel system environmental remediation.